What Are the Technical Parameters for Heliport Wind Cone

What Are the Technical Parameters for Heliport Wind Cone?

1. Environmental Requirements

The wind cone should be able to operate normally under the following environmental conditions:

a) Ambient temperature: -40℃~+55℃;

b) Maximum wind speed: 38.9m/s.

2. Creepage Distance and Electrical Clearance

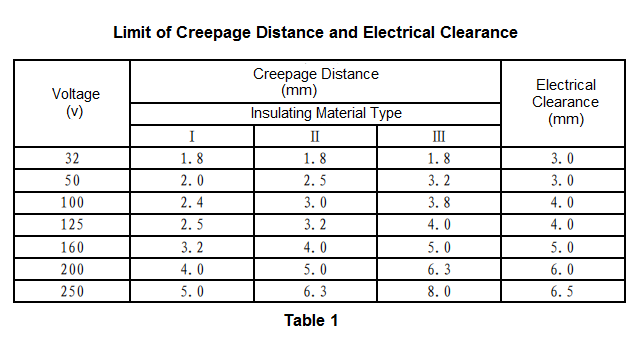

The creepage distance and electrical clearance shall not be less than the requirements in Table 1.

Divide the following four groups according to the CTI value of insulating materials:

——Insulation material type I: CTI≥600, such as glazed ceramics, mica, glass;

——Insulation material type II: 400≤CTI<600, such as melamine asbestos arc-resistant plastic, silicon organic asbestos arc-resistant plastic;

——Insulation material type IIIa: 175≤CTI<400, such as polytetrafluoroethylene plastic, tri-nitrile amine glass fiber plastic, epoxy glass cloth board treated with arc-resistant paint;

——Insulation material type IIIb: 100≤CTI<175, such as phenolic plastics and laminated products.

Note: CTI (Compared to Tracking Index): The surface of the material can withstand 50 drops of electrolyte

(0.1% ammonium chloride aqueous solution) without forming the highest voltage value of leakage trace.

3. Fabric Windsock Requirements

3.1 Fabric and process requirements

The fabric and process requirements are as follows:

a) When the fabric windsock is filled with air, its shape should be frusto-conical;

b) The easily worn and deformed parts of the metal bracket should be reinforced;

c) The fabric windsock should be moved and replaced without the use of special tools or splicing operations;

d) The accumulated water in the fabric windsock should be automatically discharged from the bag frame;

e) The fabric windsock should be made of cotton, synthetic materials or a mixture of both. If the cotton itself is not waterproof, it should be treated with waterproofing.

3.2 Dimensions

The minimum effective length of the windsock and the diameter of the air inlet should meet the requirements of MH 5001 and MH 5013:

a) S-1: The minimum effective length is 3.6m, and the diameter of the air inlet is not less than 0.9m;

b) S-2: The minimum effective length is 2.4m, the diameter of the air inlet is not less than 0.6m, and the diameter of the air outlet is not less than 0.3m;

c) S-3: The minimum effective length is 1.2m, the diameter of the air inlet is not less than 0.3m, and the diameter of the air outlet is not less than 0.15m.

3.3 Color

The windsock should be orange and white or red and white alternately (black and white can be used for the heliport), arranged in five alternately colored rings, with orange or red rings at both ends, and should meet MH 5001-2013 Appendix I Requirement; there should be no words or patterns on the windsock.

3.4 Minimum breaking strength

The minimum breaking strength of the windsock in the warp and weft directions should not be less than 667N.

3.5 Color fastness

The color fastness of the windsock should meet the test requirements of GB/T 8427, and the color difference after aging of the sample should be less than 2 levels.

4. Wind Sock Frame

4.1 The wind sock frame shall meet the following requirements:

a) The frame should keep the air inlet fully open and form a certain internal support space under no wind conditions;

b) The frame should be made of lightweight materials;

c) The frame is made of metal or non-metal materials, and non-ferrous metal materials should be hot-dip galvanized or anti-corrosion coating treatment;

d) The frame should be designed to prevent the windsock from accumulating water, and support the windsock at a rigid position three-eighths of its length;

e) The whole of the frame connected by the windsock shall have the function of a wind cone, and its bearings, wind driven shafts and similar equipment shall be lubricated permanently or regularly.

4.2 Tensile capacity of windsock

The windsock or accessories should be able to withstand the following tensile forces without deformation:

a) Style Ⅰ: 200N;

b) Style Ⅱ: 450N.

5. Supporting Structure

Typical supporting structures are shown in Figures 1 to 4 in Appendix A, and the dimensions shown should meet the following requirements:

5.1 L-806 type

The supporting structure should be easy to assemble and maintain. When fixed, the easy-to-fold part should be able to withstand the bending moment of 475N·m without being damaged, and it should be broken before being subjected to the bending moment of 950N·m. The distance from the lower end of the wind sock frame to the ground should not be less than 1.8m.

5.2 L-807 type

The supporting structure should be installed on the top or middle, with lifting function. The bracket should be able to withstand a force of 4340N·m without being damaged. The lower end of the wind sock frame should be 4.8m from the ground. The total height should be as low as possible while meeting the specified lighting requirements.

5.3 L-808 type

The supporting structure should be easy to assemble and maintain. The distance from the lower end of the wind sock frame to the ground should not be less than 1.8m.

6. Windsock Movement

The windsock should be able to rotate freely perpendicular to the axis. When the wind speed exceeds 1.6m/s, the deviation angle between the direction of the windsock and the actual wind direction should not be greater than 5°

7. Windsock Expansion

The tapered design of the windsock from the air inlet to the tail end should be able to open completely when the wind speed is 7.8 m/s.

8. Optical Performance

The lighting fixtures should not have glare affecting the pilot.

8.1 Style I-A type

There should be sufficient lighting equipment, and the illuminance value of any point on the horizontal surface when rotating on the fully extended cone is not less than 21.5 lx.

8.2 Style I-B type

There should be a backup light source to ensure that the wind cone can still operate normally when the main light source fails. When the windsock rotates freely with the wind, the light source power supply device should work normally. The top and side adopt style Ⅰ-B windsock, the average brightness value of its surface should be (34.3~102.8) cd/m2, and the brightness value at any point should not be less than 6.9cd/m2.

9. Obstruction Lights

If the wind cone is equipped with obstruction lights, the obstruction lights should be installed on the top of the wind cone.

10. Surface Spraying

The spray color of the wind cone surface should meet the requirements of MH 5001-2013 Appendix I. All exposed and corrosive weathervane metal components shall be treated with anticorrosive painting.

CONTACT ME VIA BELOW FOR ANY INQUIRY.

Shenzhen Anhang Technology Company Limited

Anhang Technology(HK) Limited

(Ms.) Dana Xiong

Mob : +8615013635584(available on Wechat, Whatsapp)

Email: dana@annhung.com

Anhang Technology(HK) Company Limited

all rights reserved © ICP:12060043