Final approach and takeoff area (FATO)

Final approach and takeoff area (FATO). A general aviation heliport has at least one FATO.

The FATO contains a TLOF within its borders at which arriving helicopters terminate their approach and

from which departing helicopters take off.

a. FATO size.

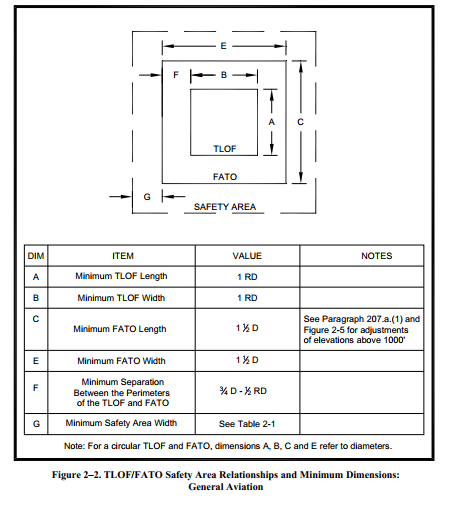

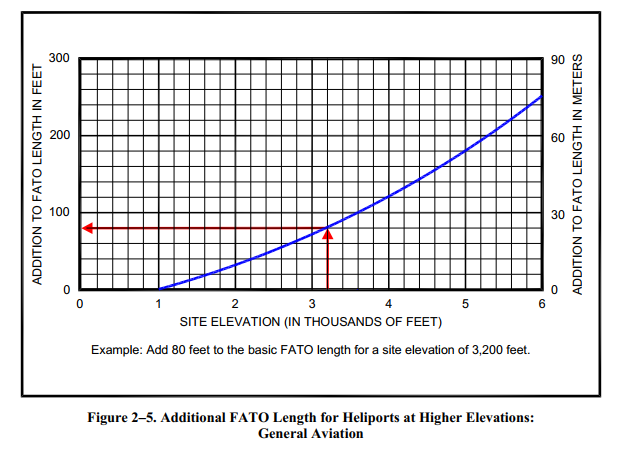

(1) Design the minimum width, length, or diameter of a FATO to be at least 1.5 times the overall length (D) of the design helicopter. Design the FATO to be circular or rectangular, regardless of the shape of the TLOF. At elevations above 1,000 feet MSL, include a longer, rectangular FATO to provide an increased safety margin and greater operational flexibility. Use the additional FATO length depicted in Figure 2–5. Where the operator of a PPR heliport chooses not to provide additional FATO length, the operator makes sure that all pilots using the facility are thoroughly knowledgeable with this and any other facility limitations.

(2) Design the minimum distance between the TLOF perimeter and the FATO perimeter to be not less than the distance (¾ D - ½ RD) where D is the overall length and RD is the rotor diameter of the design helicopter. Note that if the TLOF and FATO are not of similar shape, this applies at all points of the TLOF perimeter. The relationship of the TLOF to the FATO and the safety area is shown in Figure 2–2

b. FATO surface characteristics. If the heliport operator marks the TLOF, the FATO outside the TLOF need not load-bearing.

(1) Ground level public general aviation heliports. If the heliport operator does not mark the TLOF , and/or intends that the helicopter be able to land anywhere within the FATO, design the FATO outside the TLOF and any FATO supporting structure, like the TLOF, to be capable of supporting the dynamic loads of the design helicopter.

(2) Ground level PPR heliports. If the heliport operator does not mark the TLOF, and/or intends for the helicopter to be able to land anywhere within the FATO, design the FATO outside the TLOF and any FATO supporting structure, like the TLOF, to be capable of supporting the dynamic loads of the design helicopter.

(3) Elevated heliports. As an option, design the FATO outside the TLOF to extend into clear airspace. However, there are some helicopter performance benefits and increased operational flexibility if the FATO outside the TLOF is load bearing. Design the FATO outside of the TLOF to be load-bearing, or increase the minimum width and length or diameter of TLOF to the overall length of the design helicopter.

(4) Elevated PPR heliports. For elevated PPR heliports, if the heliport operator intends to mark the TLOF, as an option design the FATO outside the TLOF and the safety area to extend into the clear airspace (see Figure 2–4). If the heliport operator does not mark the TLOF, and/or intends that the helicopter be able to land anywhere within the FATO, design the FATO outside the TLOF and any FATO supporting structure, like the TLOF, to support the dynamic loads of the design helicopter. As an option, increase the length and width or diameter of the LBA without a corresponding increase in the size of the FATO.

(5) If the FATO is load-bearing, design the portion abutting the TLOF to be contiguous with the TLOF, with the adjoining edges at the same elevation.

(6) If the FATO is unpaved, treat the FATO to prevent loose stones and any other flying debris caused by rotor downwash.

(7) When the FATO or the LBA in which it is located is elevated 4 feet (1.2 m) or more above its surroundings, part 1910.23 requires the provision of fall protection. The FAA recommends such protection for all platforms elevated 30 inches (76 cm) or more. However, do not use permanent railings or fences since they would be safety hazards during helicopter operations. As an option, install a safety net meeting state and local regulations but not less than 5 feet (1.5 m) wide. Design the safety net to have a load carrying capability of 25 lbs/sq ft (122 kg/sq m). Make sure the net does not project above the level of the TLOF. Fasten both the inside and outside edges of the safety net to a solid structure. Construct nets of materials that are resistant to environmental effects.

c. Mobile objects within the FATO. The FATO design standards of this AC assume the TLOF and FATO are closed to other aircraft if a helicopter or other mobile object is within the FATO or the safety area.

d. Fixed objects within the FATO. Remove all fixed objects projecting above the FATO elevation

except for lighting fixtures, which may project a maximum of 2 inches (5 cm). For ground level heliports, remove all above-ground objects to the extent practicable.

e. FATO/FATO separation. If a heliport has more than one FATO, separate the perimeters of the

two FATOs so the respective safety areas do not overlap. This separation assumes simultaneous

approach/departure operations will not take place. If the heliport operator intends for the facility to

support simultaneous operations, provide a minimum 200 foot (61 m) separation.

Safety area. A safety area surrounds a FATO.

a. Safety area width. The standards for the width of the safety area are shown in Table 2-1. The value is the same on all sides. The provision or absence of standard heliport markings affects the width standards. As an option, design the safety area to extend into clear airspace.

b. Mobile objects within the safety area. The safety area design standards of this AC assume the TLOF and FATO are closed to other aircraft if a helicopter or other mobile object is within the FATO or the safety area.

c. Fixed objects within a safety area. Remove all fixed objects within a safety area projecting above the FATO elevation except for lighting fixtures, which may project a maximum of 2 inches (5 cm). For ground level heliports, remove all above-ground objects to the extent practicable.

d. Safety area surface. The safety area need not be load bearing. Figure 2–6 depicts a safety area extending over water. If possible, design the portion of the safety area abutting the FATO to be contiguous with the FATO with the adjoining edges at the same elevation. This is needed to avoid the risk of catching a helicopter skid or wheel. Clear the safety area of flammable materials and treat the area to prevent loose stones and any other flying debris caused by rotor wash.

Anhang Technology(HK) Company Limited

all rights reserved © ICP:12060043